13. Rating Procedure

13.1 The supercharge rating of the sample fuel is determined by comparison of its knock-limited power curve to the knock-limited power curves of two bracketing reference fuels.

13.1.1 The compositions of the reference fuel blends that are employed for this method are shown in Table 4.

13.2 The knock-limited power curve of either a sample or reference fuel is determined by measuring the power output (IMEP) of the engine as a function of fuel-air ratio.

13.2.1 The accepted knock-limited power curves for the set of reference fuels specified for this test method are plotted in Fig. A2.2.

13.2.2 The curves of the reference fuel framework (Fig. A2.2) were adopted with the initial issue of the test method and are used as criteria for determining acceptable limits of engine performance for every sample rating.

13.3 A minimum of six points (pairs of IMEP and fuel-air ratio data) are required to define each of the three knock-limited power curves (one for the sample fuel and two for the bracketing reference fuels) needed to determine a sample fuel rating. See Fig. A2.4 as an example of a fuel rating.

13.3.1 The IMEP points must be determined in the range of fuel-air ratios from 0.75 to 1.30 and meet the following criteria:

13.3.2 The measured IMEP values must pass through a maximum value.

13.3.2.1 The maximum IMEP value must be demonstrated by obtaining at least one measured IMEP at a fuel-air ratio greater than that of the maximum IMEP.

NOTE 1 - It has been found that some experimental aviation gasoline compositions do not reach a maximum IMEP value at fuel-air ratios below 1.3. However, supercharge ratings for these samples may still be calculated by interpolation of the bracketing reference fuels as described below.

13.3.3 At least one IMEP point must be obtained at a fuel-air ratio between 0.75 and 0.90.

13.3.4 At least four IMEP points must be obtained at fuel-air ratios less than that of the maximum IMEP.

13.4 Engine Operation for Obtaining Knock-Limited Power Curve:

13.4.1 Operate the engine on an aviation gasoline or reference fuel blend in compliance with the basic engine and instrumentation settings and standard operating conditions for approximately one hour to bring the unit to temperature equilibrium.

13.4.2 Purge the warm-up fuel from the pump and lines and switch to the first fuel (sample or reference fuel) to be tested.

13.4.3 Starting at a low manifold pressure, adjust the manifold pressure and fuel flow rate to establish standard knock intensity at a fuel-air ratio between 0.75 and 0.90.

13.4.4 After establishing standard knock intensity, allow conditions to stabilize and obtain measurements of the fuel and air consumption rates, BMEP and FMEP.

13.4.4.1 Various techniques for making the adjustments to manifold pressure and fuel flow have been utilized, depending on equipment configuration (extent of computerized control and measurement) and operator preference. Appendix X1 contains an example of an acceptable technique for manually establishing standard knock intensity and obtaining the related data.

13.4.5 Calculate IMEP and plot the result as the ordinate on a reference fuel framework (Fig. A2.2) with the fuel-air ratio as the abscissa.

NOTE 2 - It is recommended that the individual IMEP/fuel-air ratio points each be plotted when determined. This allows for immediate evaluation of the reference fuel data points for compliance with the fit-for-use criteria.

13.4.6 Make additional measurements of IMEP and fuel-air ratio data at various manifold pressures until the requirements for defining the knock-limited power curve of the fuel have been met.

13.4.7 Purge the first fuel from the pump and lines, switch to the next fuel and repeat the process to define the knock-limited power curve for the two remaining fuels.

14. Calculation of Supercharge Rating

14.1 Obtain the knock-limited power curve for each fuel by fitting a smooth curve to the set of IMEP/fuel-air ratio points that were determined for the fuel.

14.1.1 This task has historically been accomplished by manually applying a French curve or flexible ruler to the data points.

14.1.2 Use of peak-fitting computer software is currently recommended to obtain the best curve fit to the data.

NOTE 3 - The Lorentzian peak function has been successfully applied using commercially available peak-fitting software to test data generated by the Aviation NEG in recent years.

14.1.3 Determine the fuel-air ratio that corresponds to the maximum IMEP value on the knock-limited power curve of the lower bracketing reference fuel.

14.1.4 Evaluate the knock-limited power curves of the sample and upper bracketing reference fuel to determine the IMEP values of these fuels at the same fuel-air ratio as that of the maximum IMEP for the lower bracketing reference fuel.

14.1.5 Calculate the supercharge rating of the sample by interpolation of these IMEP values using the corresponding ratings of the bracketing reference fuels, as follows:

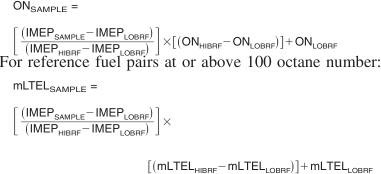

For reference fuel pairs of 100 and lower octane number:

where:

ON SAMPLE = supercharge rating of a sample fuel at or below 100 octane number,

mLTEL SAMPLE = supercharge rating of a sample fuel greater than 100 octane number,

IMEP SAMPLE = IMEP value on the knock-limited power curve of the sample fuel at the same fuel-air ratio as that of the maximum

IMEP of the knock-limited power curve of the lower bracketing reference fuel,

IMEP LOBRF = maximum IMEP of the knock-limited power curve for the lower bracketing reference fuel,

IMEP HIBRF = IMEP value on the knock-limited power curve of the upper bracketing reference fuel at the same fuel-air ratio as that of the maximum IMEP of the knock-limited power curve of the lower bracketing reference fuel,

ON LOBRF = octane number of the lower bracketing reference fuel,

ON HIBRF = octane number of the upper bracketing reference fuel,

mLTEL LOBRF = mL TEL per U.S. gallon of the lower bracketing reference fuel, and

mLTEL HIBRF = mL TEL per U.S. gallon of the upper bracketing reference fuel.

NOTE 4 - If the blends of TEL in isooctane were analyzed for tetraethyl lead content, the determined values for mL TEL may be substituted in the formulas above.

14.1.5.1 In rare instances, the knock-limited power curves of the sample fuel or one of the reference fuels (or both) are displaced along the horizontal fuel-air axis in such a manner that vertical interpolation of the IMEP data is not possible. In these instances, apply the above interpolation formula with the following modifications: set IMEP SAMPLE equal to the value at the intersection of the sample fuel knock-limited power curve with a straight line that connects the maximum IMEP values of the knock-limited power curves for the two bracketing reference fuels, and set IMEP HIIBRF equal to the maximum IMEP of the knock-limited power curve for the upper bracketing reference fuel.